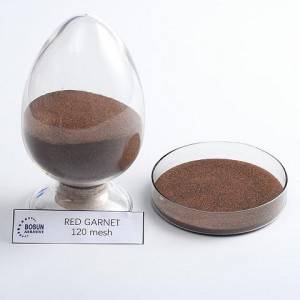

Dur Di-staen Cut Wire Shot

Disgrifiad byr:

FEATURES Stainless steel shot is delicately with the process of drawing, cutting, and conditioned etc. and with the appearance of brightness, restlessness and spherical beads (for cut wire shot, cylinders). And they are widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc.. Thus the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting ru...

NODWEDDION

saethu dur di-staen yn ofalus gyda'r broses o arlunio, torri, ac yn cyflyru ac ati a gyda ymddangosiad disgleirdeb, aflonyddwch a gleiniau sfferig (ar gyfer ergyd gwifren torri, silindrau). Ac maent yn cael eu defnyddio'n eang ar gyfer paratoi arwyneb trwy peening a ffrwydro ar Copr, alwminiwm, sinc a darnau o waith dur di-staen ac ati .. Felly gall y gwaith yn dangos eu lliw metel gydag effeithiau is-golau ac yn marw castio aflonydd ar ôl paratoi. Nid oes angen i fabwysiadu rhwd symud triniaeth gan glanhau asid. Heblaw eu abrasion gwrthiant yw 3-5 gwaith cymaint nag ergyd cast dur di-staen, fel y gallai y cynhyrchiad yn cael ei dorri i lawr.

math

Gwneud cais i offer

Stainless Steel Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Pecyn

We can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirement

DATA TECHNEGOL

|

enw |

Dur Di-staen Shot |

|

|

Cyfansoddiad cemegol |

C |

≤0.12% |

|

Mn |

≤2.00% |

|

|

Si |

≤1.00% |

|

|

Cr |

17~19% |

|

|

Ni |

7~10% |

|

|

S |

≤0.03% |

|

|

P |

≤0.035% |

|

|

caledwch |

41~59 HRC(388~509HV) |

|

|

Gwyriad caledwch |

Max Gwyriad ± 3.0HRC neu ± 40HV |

|

|

Strwythur Mettallographical |

Longitudinal(Even deformation austenitic) Horizontal(Even deformation austenitic) |

|

|

maint |

0.4-3.0mm |

|

|

Min Dwysedd (Gellir ei benderfynu gan dadleoli alcoholig) |

7.8g / cm3 |

|

PS: Gall ein cwmni yn unol â gofynion y cwsmer arbennig, yn darparu cyfansoddiad cemegol eraill y saethu dur di-staen.

|

C |

Cr |

Ni |

Si |

Mn |

|

|

304 awstenitig |

<0.25% |

16~18% |

6~10% |

<1% |

<2% |

|

201 awstenitig |

<0.15% |

16~18% |

3.5~5.5% |

<1% |

5.5~7.5 |

|

430 Ferritic |

<0.25% |

16~18% |

<1% |

<1% |

ef achos economaidd dros ddefnyddio di-staen ergyd gwifren torri mewn peening a chwyth gweithrediadau glanhau yn eithaf hawdd i'w wneud. Nid yw torri gwifren yn torri neu torri i lawr yn ystod eu defnyddio oherwydd ei fod yn ddarn solet. O ganlyniad nifer o bethau cadarnhaol yn digwydd:

● Stainless cut wire shot has a significantly longer useful life than cast steel shot or grit and carbon cut wire shot

● Dust generation is significantly lower so blasting operations are much cleaner

● Stainless cut wire produces excellent results because of its uniformity and strength

● It will make you a “Greener” organization because disposal of spent media will be significantly reduced (You won’t need as much shot, inventory requirements will be lower and in-bound freight less)

● You will NOT introduce ferrous contamination to non ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot

CAIS

Clean: blasting cleaning; pressure casting cleaning; magnesium alloy, zinc alloy, aluminum alloy and copper alloy casting fettling; stainless steel casting cleaning; stainless steel plate cleaning; stainless steel products cleaning; Colored pieces surface deburring and lighting processing, it can improve the fatigue resistance, anti-corrosion properties and cover casting surface defect, also make the product surface good.

Derust: shot blasting ; derusting casting; forgings derusting; Steel plate rust removal; steel products rust removal;

Dwysáu: dur di-staen yn cynhyrchu dwysáu; darnau drin â gwres arwyneb dwysáu;

Ffrwydro: magnesium alloy, zinc alloy, aluminum alloy and copper alloy cast blasting; stainless steel products blasting.