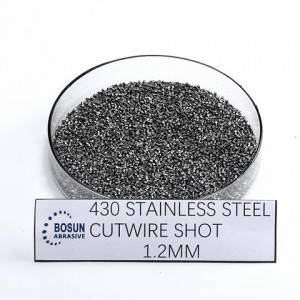

Stainless Steel Cut terata Shot

Short Tlhaloso:

FEATURES Stainless steel shot is delicately with the process of drawing, cutting, and conditioned etc. and with the appearance of brightness, restlessness and spherical beads (for cut wire shot, cylinders). And they are widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc.. Thus the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting ru...

LIKAROLOANA

Celik thunngoa ke delicately le tshebetso ya ho kotokaka, ho itšeha le masusu jj le ka ponahalo ea khanya, restlessness le lifaha chitja (bakeng sa sehiloeng terata thunngoa, diselennere). 'Me ba ho pharaletseng sebelisoa bakeng sa ho lokisetsa holim ke peening le ho qhomisa e ka Koporo, Aluminium, zinki le glassware likotoana tšepe mosebetsi jj .. Kahoo mosebetsi ka mohlala tšepe' mala ea bona le litla-potlana leseli 'me shoa lahla restlessness mora lokisetsa. Ho na le ke ho hlokahale hore ho amohela mafome fallela kalafo ke acid e hloekisa. Ntle abrasion bona hanyetsa ke linako tse 3-5 ka haholo ho feta liheloe celik thunngoa, kahoo o fana ka tlhahiso ea ka ho e rema.

mofuta

Sebetsa ho thepa

Stainless Steel Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Sephutheloana

We can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirement

Data Technical

|

lebitso |

Stainless Steel Shot |

|

|

lik'hemik'hale Sebopeho |

C |

≤0.12% |

|

MN |

≤2.00% |

|

|

Si |

≤1.00% |

|

|

Kr |

17~19% |

|

|

Ni |

7~10% |

|

|

S |

≤0.03% |

|

|

P |

≤0.035% |

|

|

thatafala |

41~59 HRC(388~509HV) |

|

|

thatafala kheloha |

Max kheloha ± 3.0HRC kapa ± 40HV |

|

|

Mettallographical Sebopeho |

Longitudinal(Even deformation austenitic) Horizontal(Even deformation austenitic) |

|

|

Size |

0.4-3.0mm |

|

|

Mets kitlano (Na ho laolwa ke displacement joala) |

7.8g / cm3 |

|

PES: khampani ya rona ka ho latela ditlhoko moreki e khethehileng, ho fana ka le leng lik'hemik'hale tsa celik thunngoa.

|

C |

Kr |

Ni |

Si |

MN |

|

|

304 Austenitic |

<0.25% |

16~18% |

6~10% |

<1% |

<2% |

|

201 Austenitic |

<0.15% |

16~18% |

3.5~5.5% |

<1% |

5.5~7.5 |

|

430 Ferritic |

<0.25% |

16~18% |

<1% |

<1% |

a sebetsa nyeoe ea ka a moruo bakeng sa ho sebedisa glassware sehiloeng terata thunngoa ka peening le pululo hloekisa tshebetso ke ho le bonolo haholo ho etsa. Cut terata ha fracture kapa thipitlo nakong tšebeliso hobane ke sekhechana tiileng. Ka lebaka leo lintho tse 'maloa-positive etsahala:

● Stainless cut wire shot has a significantly longer useful life than cast steel shot or grit and carbon cut wire shot

● Dust generation is significantly lower so blasting operations are much cleaner

● Stainless cut wire produces excellent results because of its uniformity and strength

● It will make you a “Greener” organization because disposal of spent media will be significantly reduced (You won’t need as much shot, inventory requirements will be lower and in-bound freight less)

● You will NOT introduce ferrous contamination to non ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot

ITHUTANG

Clean: blasting cleaning; pressure casting cleaning; magnesium alloy, zinc alloy, aluminum alloy and copper alloy casting fettling; stainless steel casting cleaning; stainless steel plate cleaning; stainless steel products cleaning; Colored pieces surface deburring and lighting processing, it can improve the fatigue resistance, anti-corrosion properties and cover casting surface defect, also make the product surface good.

Derust: shot blasting ; derusting casting; forgings derusting; Steel plate rust removal; steel products rust removal;

Matlafatsa: celik hlahisa ho matlafatsa; mocheso hampe likotoana holim matlafatsa;

Ho qhomisa e: magnesium alloy, zinc alloy, aluminum alloy and copper alloy cast blasting; stainless steel products blasting.