igwe anaghị agba nchara Cut Waya shot

Short Description:

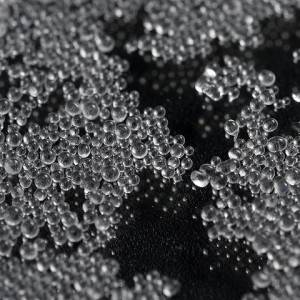

FEATURES Stainless steel shot is delicately with the process of drawing, cutting, and conditioned etc. and with the appearance of brightness, restlessness and spherical beads (for cut wire shot, cylinders). And they are widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc.. Thus the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting ru...

atụmatụ

Igwe anaghị agba nchara shot bụ ikuku na usoro nke ịbịaru, ọnwụ, na oyi wdg na na ọdịdị ìhè, erughị ala na * Tụkwasị chaplet (maka ịkpụ waya shot, cylinders). Ha na-n'ọtụtụ ebe maka n'elu nkwadebe site peening na ọgbụgba ọkụ na Ọla kọpa, Aluminium, Zinc na igwe anaghị agba nchara na-arụ ọrụ iberibe etc .. N'ihi ya ọrụ ike atụ ha metal agba na sub-ìhè mmetụta ma na-anwụ nēfe erughị ala mgbe nkwadebe. Ọ dịghị mkpa ido nchara na-akpụ akpụ ọgwụgwọ site acid ihicha. E wezụga ha abrasion eguzogide bụ 3-5 okpukpu karịa nkedo anaghị agba nchara shot, otú mmepụta ike ga-egbutu.

ụdị

Emetụta akụrụngwa

Stainless Steel Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Ngwugwu

We can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirement

data

|

aha |

igwe anaghị agba nchara Shot |

|

|

Chemical mejupụtara |

C |

≤0.12% |

|

igwe |

≤2.00% |

|

|

si |

≤1.00% |

|

|

ČR |

17~19% |

|

|

ni |

7~10% |

|

|

S |

≤0.03% |

|

|

P |

≤0.035% |

|

|

ekweghị ekwe |

41~59 HRC(388~509HV) |

|

|

ekweghị ekwe ndiiche |

Max ndiiche ± 3.0HRC ma ọ bụ ± 40HV |

|

|

Mettallographical Structure |

Longitudinal(Even deformation austenitic) Horizontal(Even deformation austenitic) |

|

|

size |

0.4-3.0mm |

|

|

Min njupụta (ike-ekpebisi ike site na-aba Ndahie) |

7.8g / cm3 |

|

PS: Anyị ụlọ ọrụ nwere ike dị ka ndị ahịa pụrụ iche chọrọ, enye ndị ọzọ chemical mejupụtara nke igwe anaghị agba nchara ogbugba.

|

C |

ČR |

ni |

si |

igwe |

|

|

304 Austenitic |

<0.25% |

16~18% |

6~10% |

<1% |

<2% |

|

201 Austenitic |

<0.15% |

16~18% |

3.5~5.5% |

<1% |

5.5~7.5 |

|

430 Ferritic |

<0.25% |

16~18% |

<1% |

<1% |

ọ aku ikpe n'ihi na site na iji igwe anaghị ịkpụ waya shot na peening na gbawara nhicha arụmọrụ bụ nnọọ mfe ime. Cut waya anaghị mgbaji ọkpụkpụ ma ọ bụ mmebi n'oge eji n'ihi na ọ bụ a siri ike ibe. N'ihi ọtụtụ ihe ndị ziri ezi ime:

● Stainless cut wire shot has a significantly longer useful life than cast steel shot or grit and carbon cut wire shot

● Dust generation is significantly lower so blasting operations are much cleaner

● Stainless cut wire produces excellent results because of its uniformity and strength

● It will make you a “Greener” organization because disposal of spent media will be significantly reduced (You won’t need as much shot, inventory requirements will be lower and in-bound freight less)

● You will NOT introduce ferrous contamination to non ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot

tinye

Clean: blasting cleaning; pressure casting cleaning; magnesium alloy, zinc alloy, aluminum alloy and copper alloy casting fettling; stainless steel casting cleaning; stainless steel plate cleaning; stainless steel products cleaning; Colored pieces surface deburring and lighting processing, it can improve the fatigue resistance, anti-corrosion properties and cover casting surface defect, also make the product surface good.

Derust: shot blasting ; derusting casting; forgings derusting; Steel plate rust removal; steel products rust removal;

Nditetịm: igwe anaghị agba nchara na-arụpụta-esiwanye ike; okpomọkụ-emeso iberibe elu-esiwanye ike;

Ọgbụgba ọkụ: magnesium alloy, zinc alloy, aluminum alloy and copper alloy cast blasting; stainless steel products blasting.