alagbara, Irin Ge Waya shot

Kukuru Apejuwe:

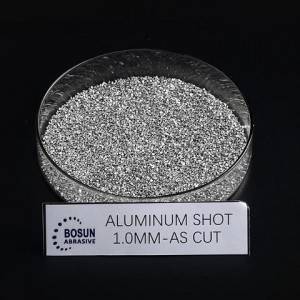

FEATURES Stainless steel shot is delicately with the process of drawing, cutting, and conditioned etc. and with the appearance of brightness, restlessness and spherical beads (for cut wire shot, cylinders). And they are widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc.. Thus the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting ru...

ẹya

Irin alagbara, irin shot ni delicately pẹlu awọn ilana ti iyaworan, Ige, ati ki o iloniniye ati be be lo ati pẹlu awọn hihan imọlẹ, àìnísinmi àti ti iyipo ilẹkẹ (fun ge waya shot, gbọrọ). Ati awọn ti wọn wa ni o gbajumo ni lilo fun awọn dada igbaradi nipa peening ati iredanu on Ejò, Aluminiomu, Sinkii ati alagbara, irin ise ona ati be be lo .. Bayi iṣẹ le akawe wọn irin awọ pẹlu iha-ina ipa ati ki o kú simẹnti àìnísinmi lẹhin ti igbaradi. Nibẹ ni ko si ye lati d'ipata gbigbe itoju nipa acid ninu. Yato si wọn abrasion resistance jẹ 3-5 igba bi Elo ju simẹnti irin alagbara, irin shot, ki isejade le wa ni ge mọlẹ.

iru

Kan si awọn eroja

Stainless Steel Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Package

We can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirement

jijẹmọ data

|

Name |

Alagbara, Irin Shot |

|

|

kemikali Tiwqn |

C |

≤0.12% |

|

Mi Ni |

≤2.00% |

|

|

si |

≤1.00% |

|

|

Kr |

17~19% |

|

|

ni |

7~10% |

|

|

S |

≤0.03% |

|

|

P |

≤0.035% |

|

|

líle |

41~59 HRC(388~509HV) |

|

|

líle iyapa |

Max iyapa ± 3.0HRC tabi ± 40HV |

|

|

Mettallographical Be |

Longitudinal(Even deformation austenitic) Horizontal(Even deformation austenitic) |

|

|

iwọn |

0.4-3.0mm |

|

|

Min iwuwo (Le wa ni ṣiṣe nipasẹ ọti-nipo) |

7.8g / cm3 |

|

PS: Wa ile le gẹgẹ bi onibara ká pataki ibeere, pese awọn miiran kemikali tiwqn ti awọn irin alagbara, irin shot.

|

C |

Kr |

ni |

si |

Mi Ni |

|

|

304 Austenitic |

<0.25% |

16~18% |

6~10% |

<1% |

<2% |

|

201 Austenitic |

<0.15% |

16~18% |

3.5~5.5% |

<1% |

5.5~7.5 |

|

430 Ferritic |

<0.25% |

16~18% |

<1% |

<1% |

o aje nla fun lilo alagbara, ge waya shot ni peening ati aruwo ninu mosi jẹ ohun ti o rorun lati ṣe. Ge waya ko ni egugun tabi didenukole nigba lilo nitori ti o jẹ a ri to nkan. Bi awọn kan abajade orisirisi ohun rere waye:

● Stainless cut wire shot has a significantly longer useful life than cast steel shot or grit and carbon cut wire shot

● Dust generation is significantly lower so blasting operations are much cleaner

● Stainless cut wire produces excellent results because of its uniformity and strength

● It will make you a “Greener” organization because disposal of spent media will be significantly reduced (You won’t need as much shot, inventory requirements will be lower and in-bound freight less)

● You will NOT introduce ferrous contamination to non ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot

APPLICATION

Clean: blasting cleaning; pressure casting cleaning; magnesium alloy, zinc alloy, aluminum alloy and copper alloy casting fettling; stainless steel casting cleaning; stainless steel plate cleaning; stainless steel products cleaning; Colored pieces surface deburring and lighting processing, it can improve the fatigue resistance, anti-corrosion properties and cover casting surface defect, also make the product surface good.

Derust: shot blasting ; derusting casting; forgings derusting; Steel plate rust removal; steel products rust removal;

Teramo: alagbara, irin fun wa intensifying; ooru-mu ege dada intensifying;

Efuufuu: magnesium alloy, zinc alloy, aluminum alloy and copper alloy cast blasting; stainless steel products blasting.