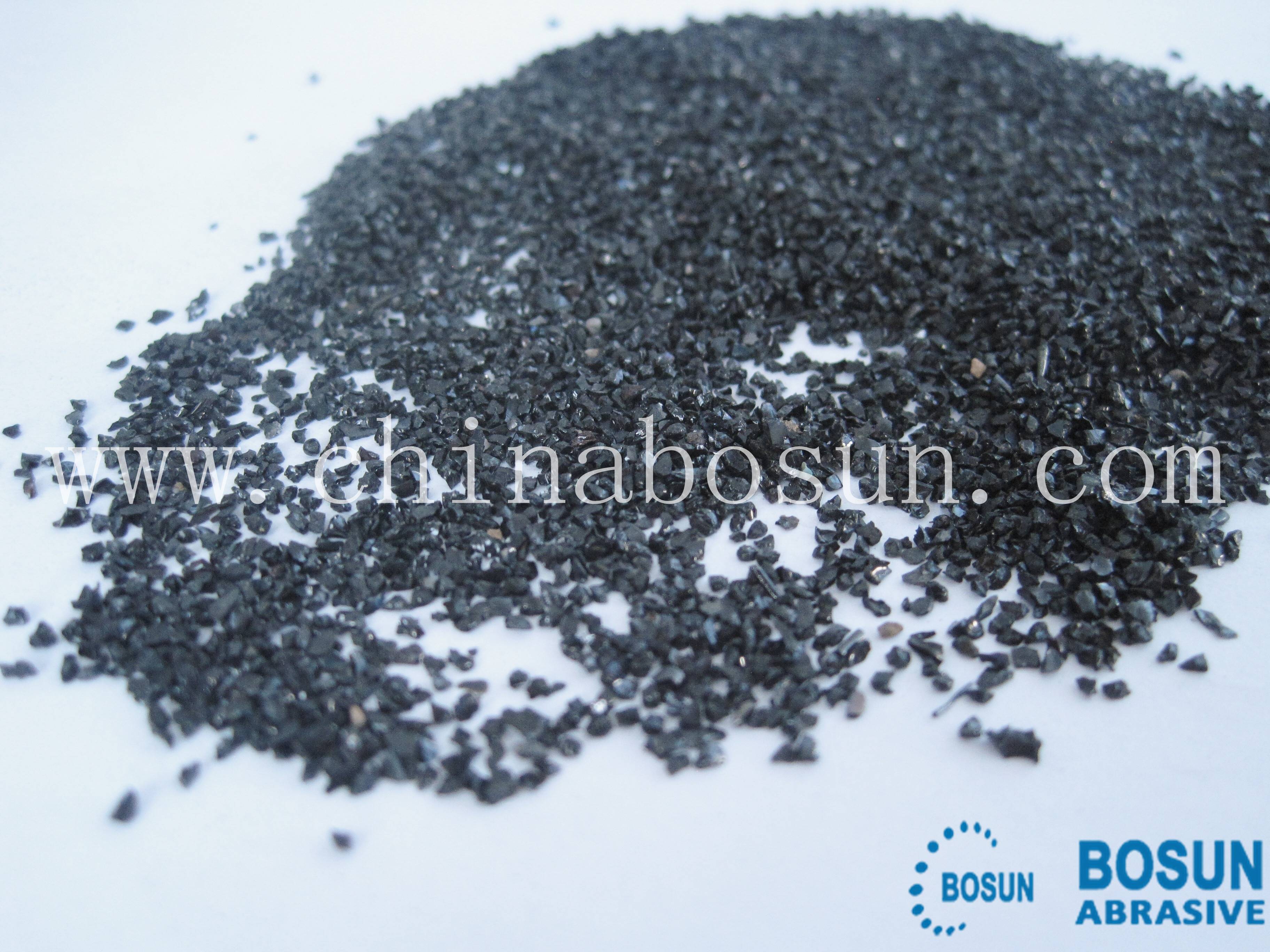

Hot New Products Black Silicon Carbide for Manufacturer

Short Description:

FEATURES Silicon carbide is made from quartz sand, petroleum coke (or char), sawdust from electric arc furnace smelting. In nature there are also rare silicon carbide mineral moissanite. Silicon carbide, also known as Moissanite. In contemporary C, N, B and other non-oxide refractory materials in high-tech, silicon carbide is the most widely used and most economical one. Can be called emery or refractory sand. Silicon carbide is with quartz sand, petroleum coke (or coal tar), wood (green sili...

Hot New Products Black Silicon Carbide for Manufacturer Detail:

FEATURES

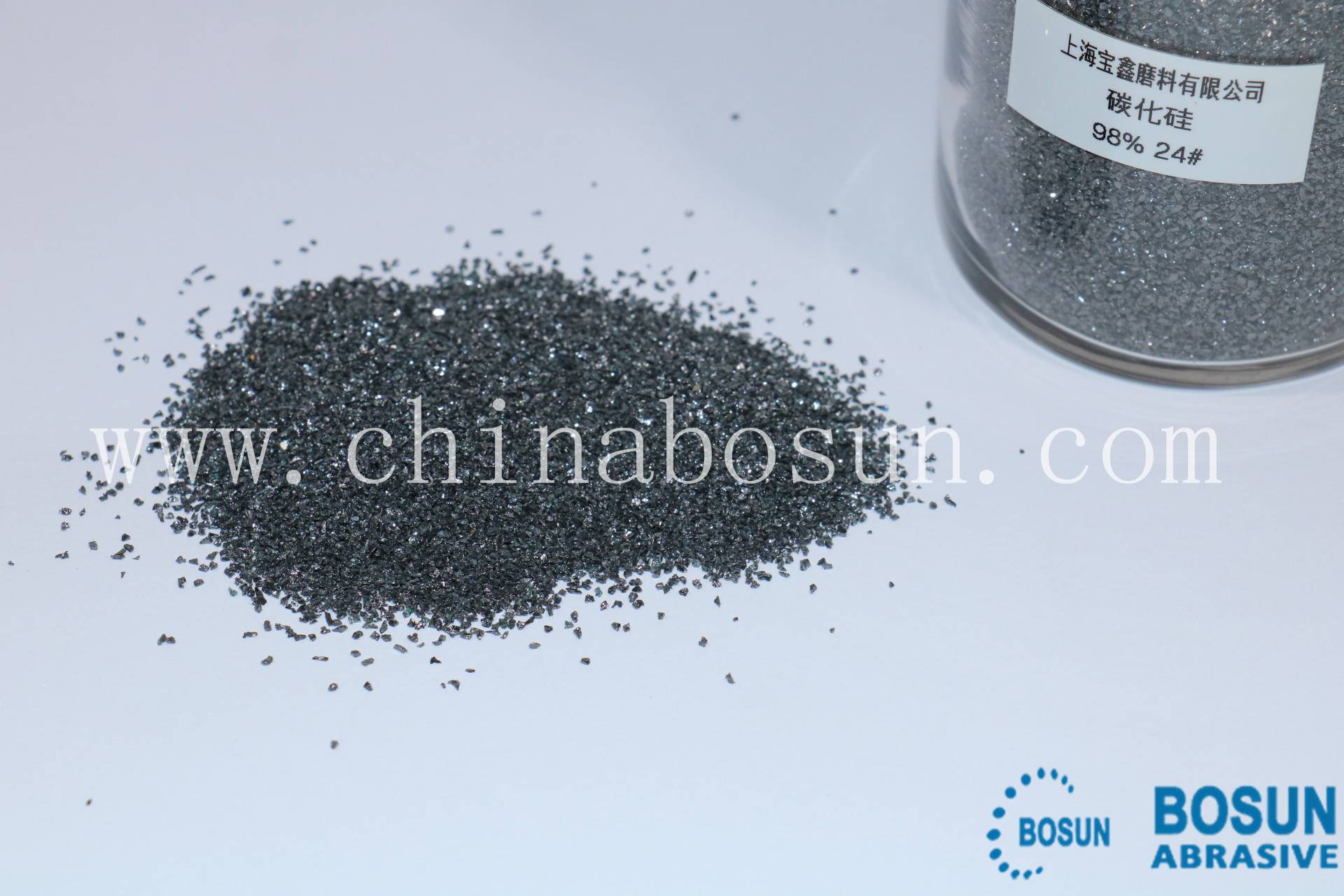

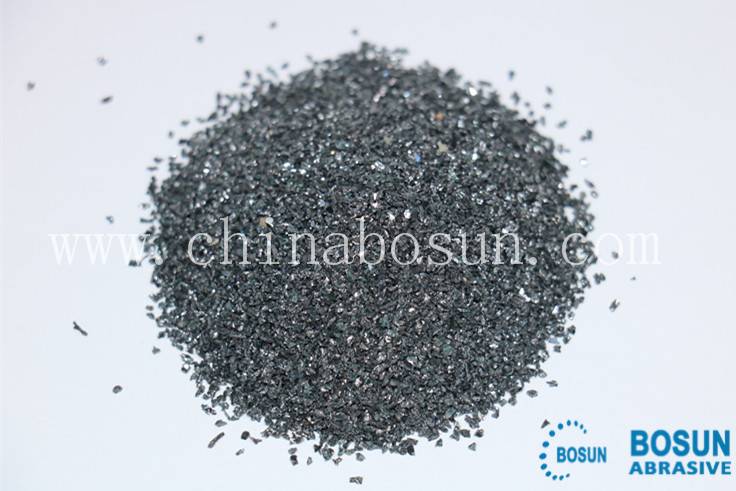

Silicon carbide is made from quartz sand, petroleum coke (or char), sawdust from electric arc furnace smelting. In nature there are also rare silicon carbide mineral moissanite. Silicon carbide, also known as Moissanite. In contemporary C, N, B and other non-oxide refractory materials in high-tech, silicon carbide is the most widely used and most economical one. Can be called emery or refractory sand. Silicon carbide is with quartz sand, petroleum coke (or coal tar), wood (green silicon carbide need to increase the production of salt) and other raw materials in high temperature resistance furnace smelting. At present China’s industrial production of silicon carbide is divided into two kinds of black silicon carbide and green silicon carbide, are hexagonal crystals, accounting for 3.20 to 3.25, microhardness 2840 ~ 3320kg/mm2

Grit size :12#-220#;

Micropowder: 240#-1200#.

Character

SIC 88%-97%,

Fe203 2.5% max,

F.C. 2.5% max,

Moisture 1.0% max.

TECHNICAL DATA

|

Size Range |

SiC ≥ |

Free carbon ≤ |

Fe2O3% ≤ |

|

|

Black silicon carbide |

12 # -90 # |

98.5 |

0.2 |

0.6 |

|

100 # -180 # |

98 |

0.3 |

0.8 |

|

|

220 # -240 # |

97 |

0.3 |

1.2 |

|

|

Green Silicon Carbide |

20 # -90 # |

99 |

0.2 |

0.2 |

|

100 # -80 # |

98.5 |

0.25 |

0.5 |

|

|

220 # -240 # |

97.5 |

0.25 |

0.7 |

|

|

W63-W20 |

97 |

0.3 |

0.7 |

|

|

W14-W10 |

95.5 |

0.3 |

0.7 |

|

|

W7-W5 |

94 |

0.3 |

0.7 |

|

APPLICATION

Product usage

1. as an abrasive, can be used for abrasives, such as grinding wheel, Whetstone, grinding, sand tile and so on.

2. as metallurgical deoxidizer and high temperature materials.

3. high purity single crystal can be used for the manufacture of semiconductor manufacturing silicon carbide fibers.

4. The modifiers can be used as a deoxidizer and a steel the cast iron structure, used as starting materials for making silicon tetrachloride, are the main raw materials of silicone resin industry.

5. High-temperature materials for indirect heating

Use for Large blast furnace lining

Application

1.Ceramics,

2.advanced refractories,

3.abrasives,

4.metallurgical raw materials,

Product detail pictures:

Related Product Guide:

Basic Information About Abrasive Garnet Processing

Benefits of Garnet Abrasives

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Hot New Products Black Silicon Carbide for Manufacturer, The product will supply to all over the world, such as: Armenia, Casablanca, Denver, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.